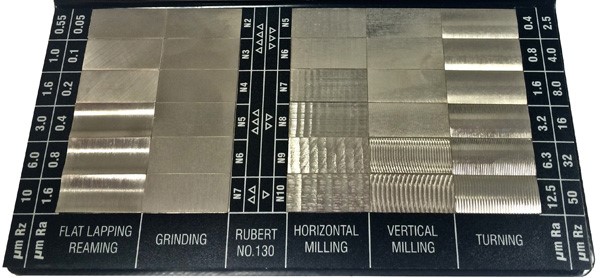

MXBAOHENG Planer sanding machines, surface roughness comparison, sample block, surface roughness contrast Ra value (6.3 3.2 1.6 0.8) UM : Amazon.de: DIY & Tools

MXBAOHENG Planer sanding machines, surface roughness comparison, sample block, surface roughness contrast Ra value (6.3 3.2 1.6 0.8) UM : Amazon.de: DIY & Tools

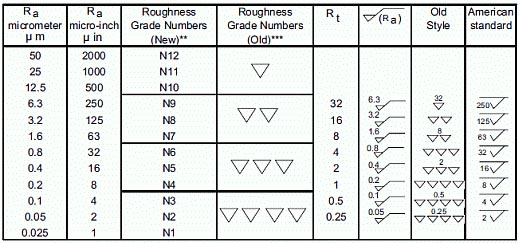

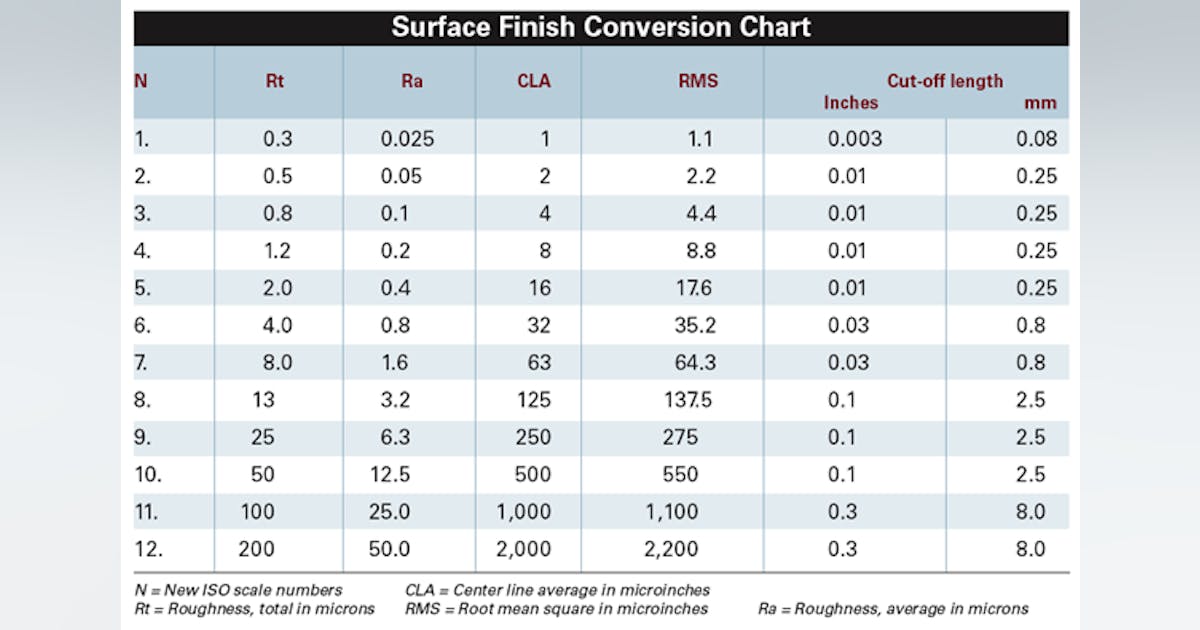

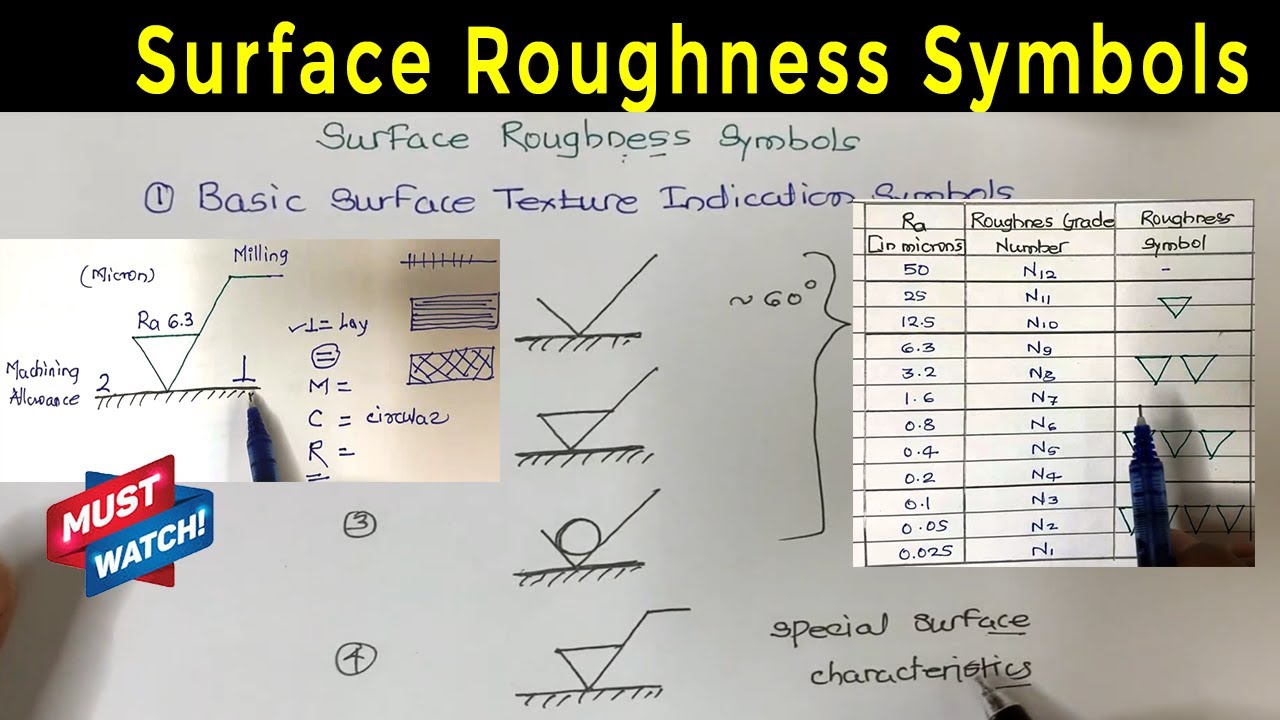

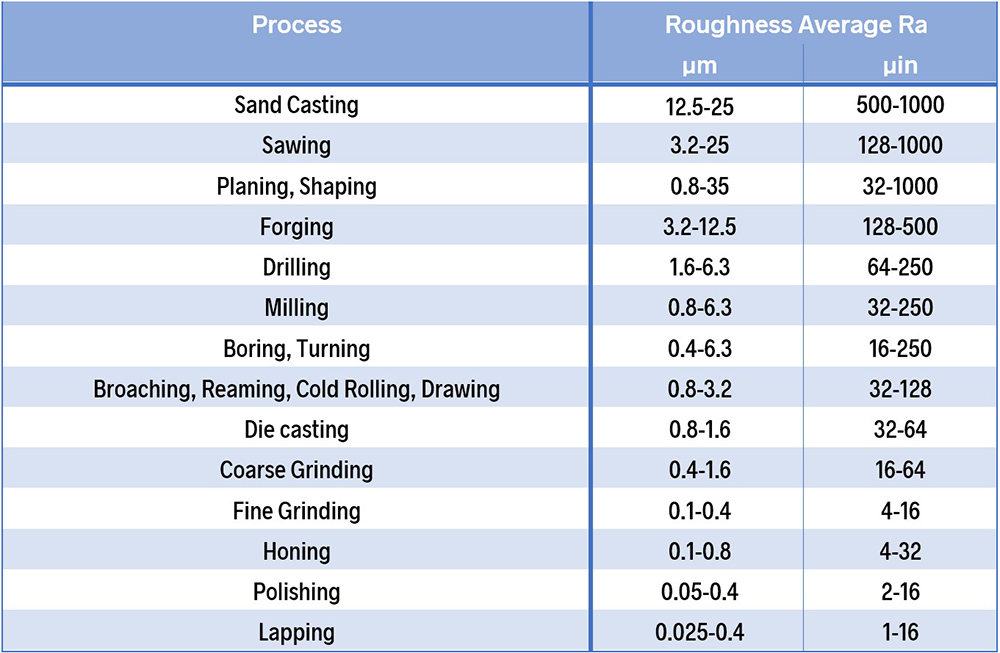

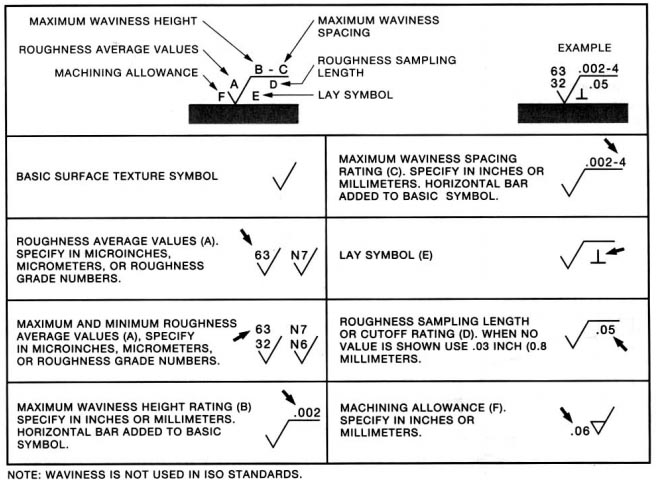

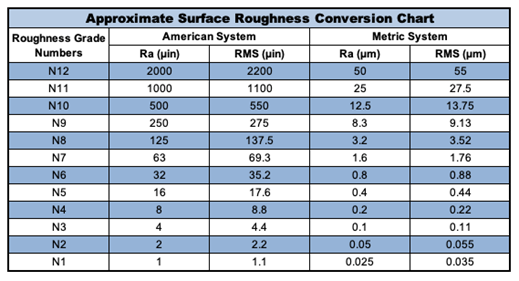

Xometry Europe - 💢 Selecting the right surface roughness for #cncmachined parts can be confusing. That is why we have made a guide for you to be able to select the best

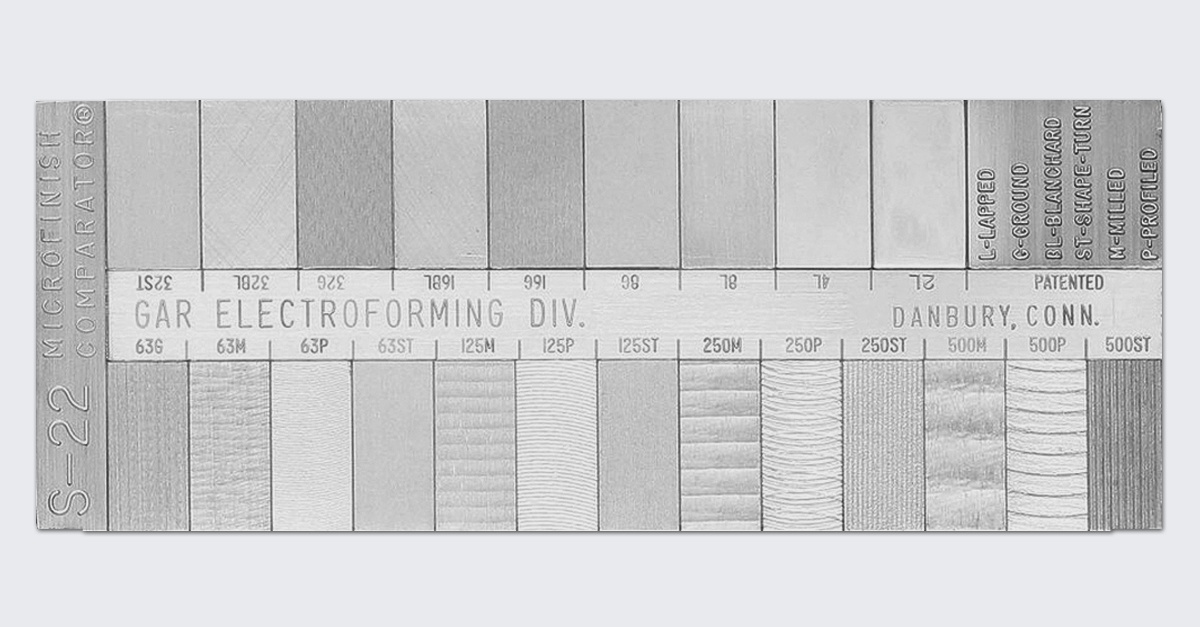

How to deal with the surface finish for your precision CNC machine parts. | CNC Precision Machining Service

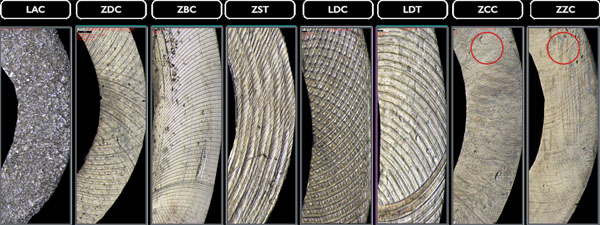

Surface Roughness and Necessity of Manual Refinishing Requirements of CAD/CAM-Manufactured Titanium and Cobalt-Chrome Bars – A Pilot Study