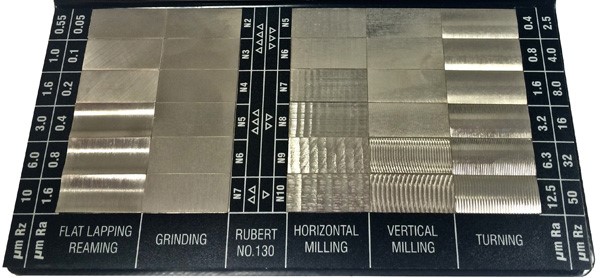

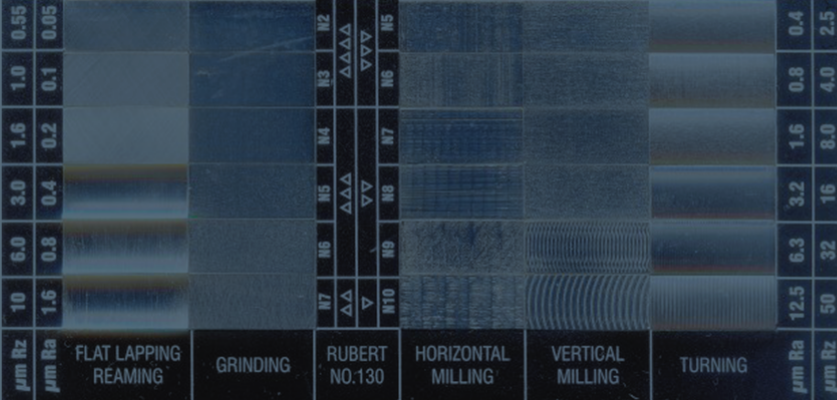

MXBAOHENG Planer sanding machines, surface roughness comparison, sample block, surface roughness contrast Ra value (6.3 3.2 1.6 0.8) UM : Amazon.de: DIY & Tools

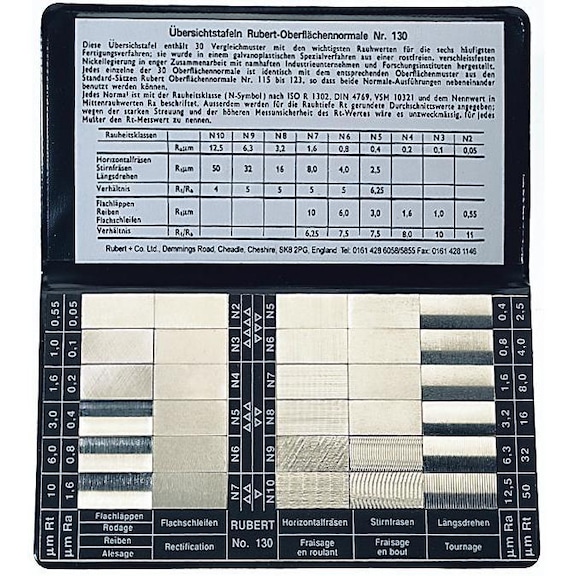

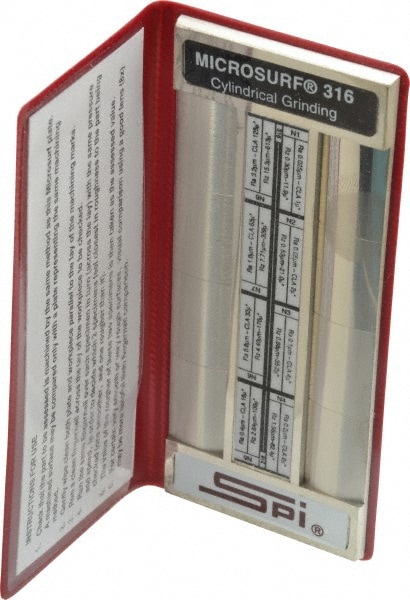

SPI - 0.025 to 3.2 RA micro m Surface Finish, Nickel, Surface Finish Comparator - 06558167 - MSC Industrial Supply

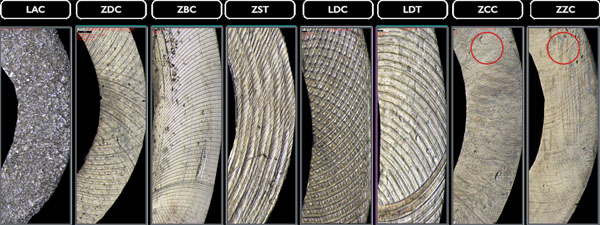

Surface Roughness and Necessity of Manual Refinishing Requirements of CAD/CAM-Manufactured Titanium and Cobalt-Chrome Bars – A Pilot Study

MXBAOHENG Sandblasted surface roughness comparison sample block Ra value (0.8 1.6 3.2 6.3 12.5) UM : Amazon.de: DIY & Tools

SPI - 0.1 to 3.2 RA micro m Surface Finish, Nickel, Surface Finish Comparator - 06558266 - MSC Industrial Supply

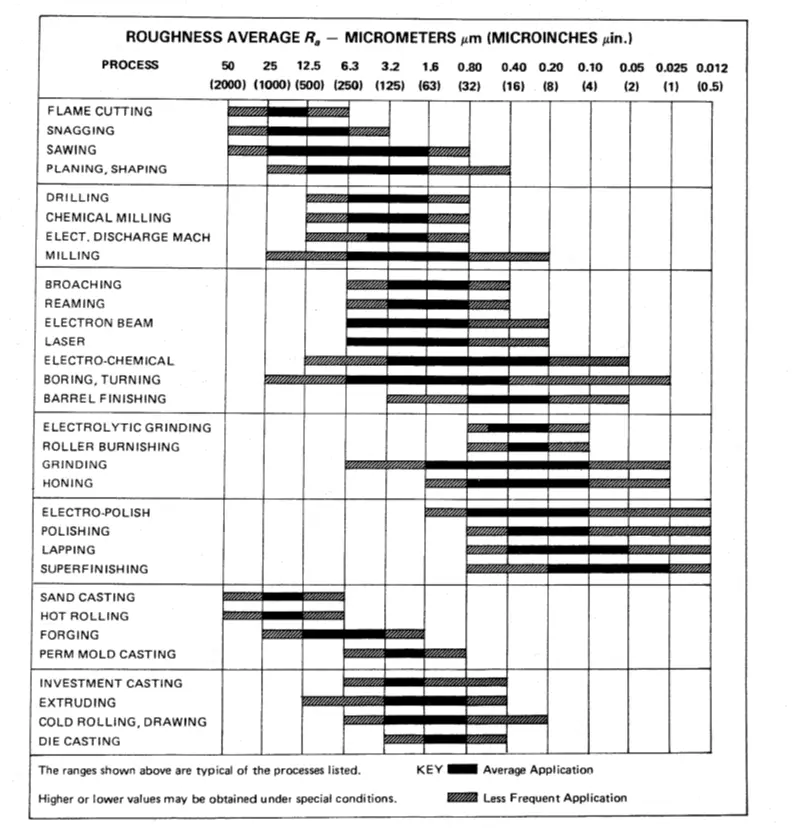

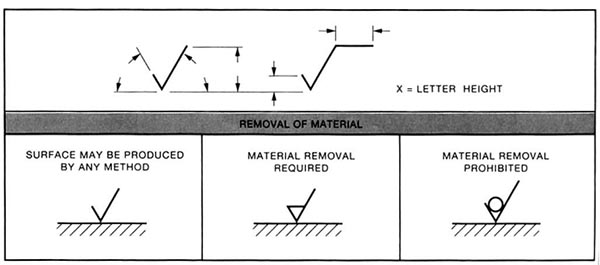

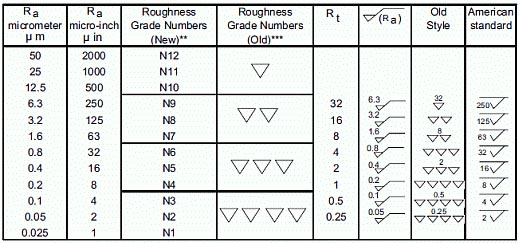

Xometry Europe - 💢 Selecting the right surface roughness for #cncmachined parts can be confusing. That is why we have made a guide for you to be able to select the best

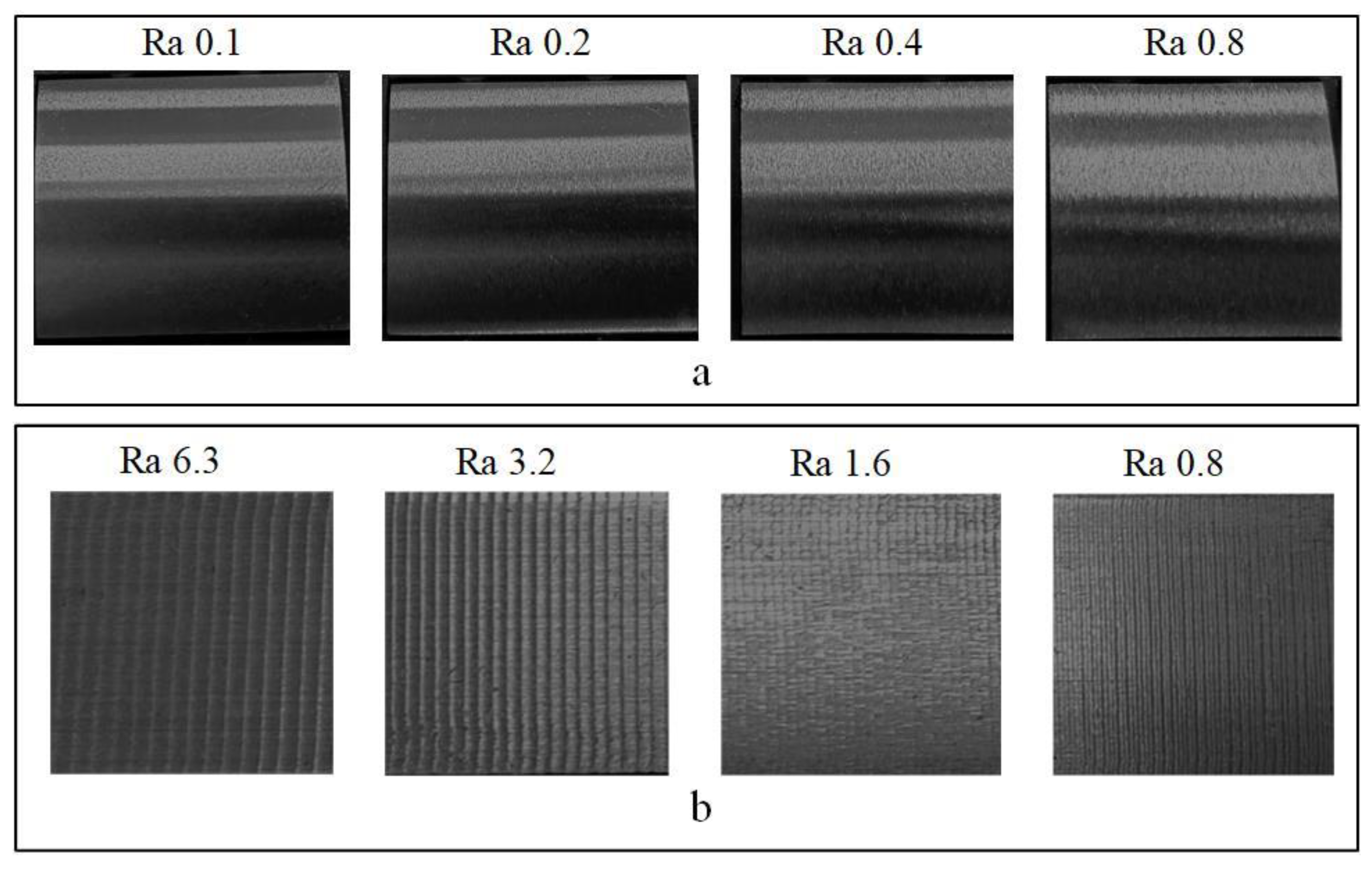

Machines | Free Full-Text | A GAN-BPNN-Based Surface Roughness Measurement Method for Robotic Grinding